Modernise Make Ready processes by digitally

transforming the way you operate

MAKE

READY

By working closely with industry experts, the Pro-Cloud Make Ready module has successfully captured everything required to ensure make ready teams can fully digitise the way they work and improve efficiencies throughout their department and service.

Whether your vehicles are being equipped for a one-off event or you have specialist emergency vehicles, the Make Ready module has the flexibility to meet a variety of make ready requirements.

New Make Ready Jobs

Every time a vehicle arrives back at a hub or station for shift change the make ready process is initiated. The tried and tested Make Ready module elevates community care by ensuring make ready tasks are completed quickly and efficiently and vehicles are ready for emergency call-outs as quickly as possible.

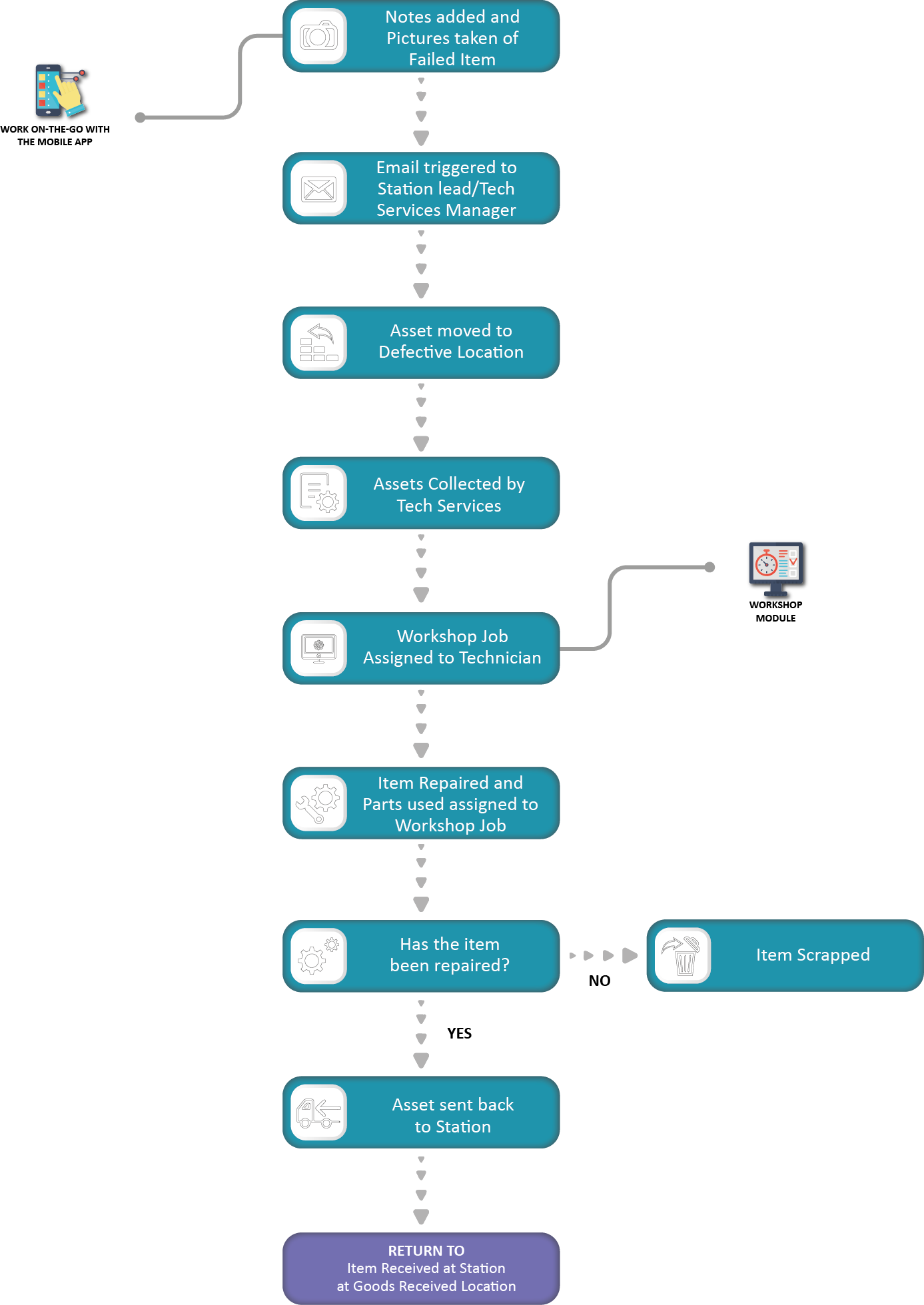

Every component of the make ready process is recorded via the Pro-Cloud app, in real-time and includes features such as:

- In cleaning

- Daily inspections

- Fuel and vehicle checks

- Workshop scheduling

- Inventory checks

- Asset packing

Make Ready Sign off Process

The aim of the Make Ready module is to ensure the entire process is completed in a timely manner and each element is thoroughly checked and recorded without fail. Inevitably, this isn’t always possible in the pre-hospital or police setting, which the system has taken into consideration and has enabled reasons to be applied for future analytical reporting.

When all make ready tasks are fulfilled a detailed questionnaire is completed to ensure the inspection has been done correctly and the vehicle is safe and ready for use. The digital make ready board is where any failed jobs are listed, issues are raised, and replacement vehicles are arranged if required. Photographic evidence can also be configured to support the process.

RFID Technology

Once the entire process is completed the job will be signed off through RFID technology, which can be active, passive or a combination of both. The inside of the vehicle is scanned and checked against the vehicles inventory list to confirm all is on board. RFID technology is a key component in increasing the speed of the process as it reads multiple equipment RFID tags simultaneously.

Click here for further information about RFID.

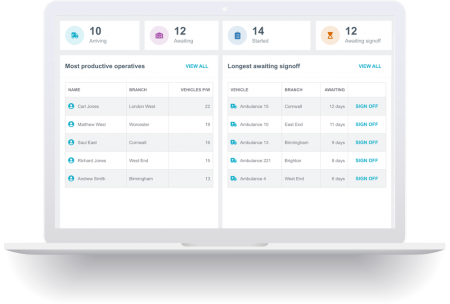

Vehicle Status Dashboard

The Vehicle Status Dashboard drills down and displays the status of a vehicle, stating if it is pending and waiting for the make-ready process to commence, if the vehicle is in preparation, or if it has been kitted out with equipment and is ready for use. It enables management teams to drill down and view:

- Incoming stock replenishments

- Jobs/priorities

- Provides a more in-depth overview compared to the app

- Individual performance data

Core benefits include:

Increased transparency on vehicle availability to respond to patient/community demand

Enhanced decisions on releasing partially kitted vehicles

Improved ability to rapidly scale operations with a real-time understanding of vehicle availability

Improved ability to troubleshoot vehicle issues and arrange for replacement vehicles

Ability for timely alignment of vehicles with crew availability