Keep stock visibility high and ensure every

movement is recorded in real time.

STOCK

MANAGEMENT

Track and trace stock levels and movements

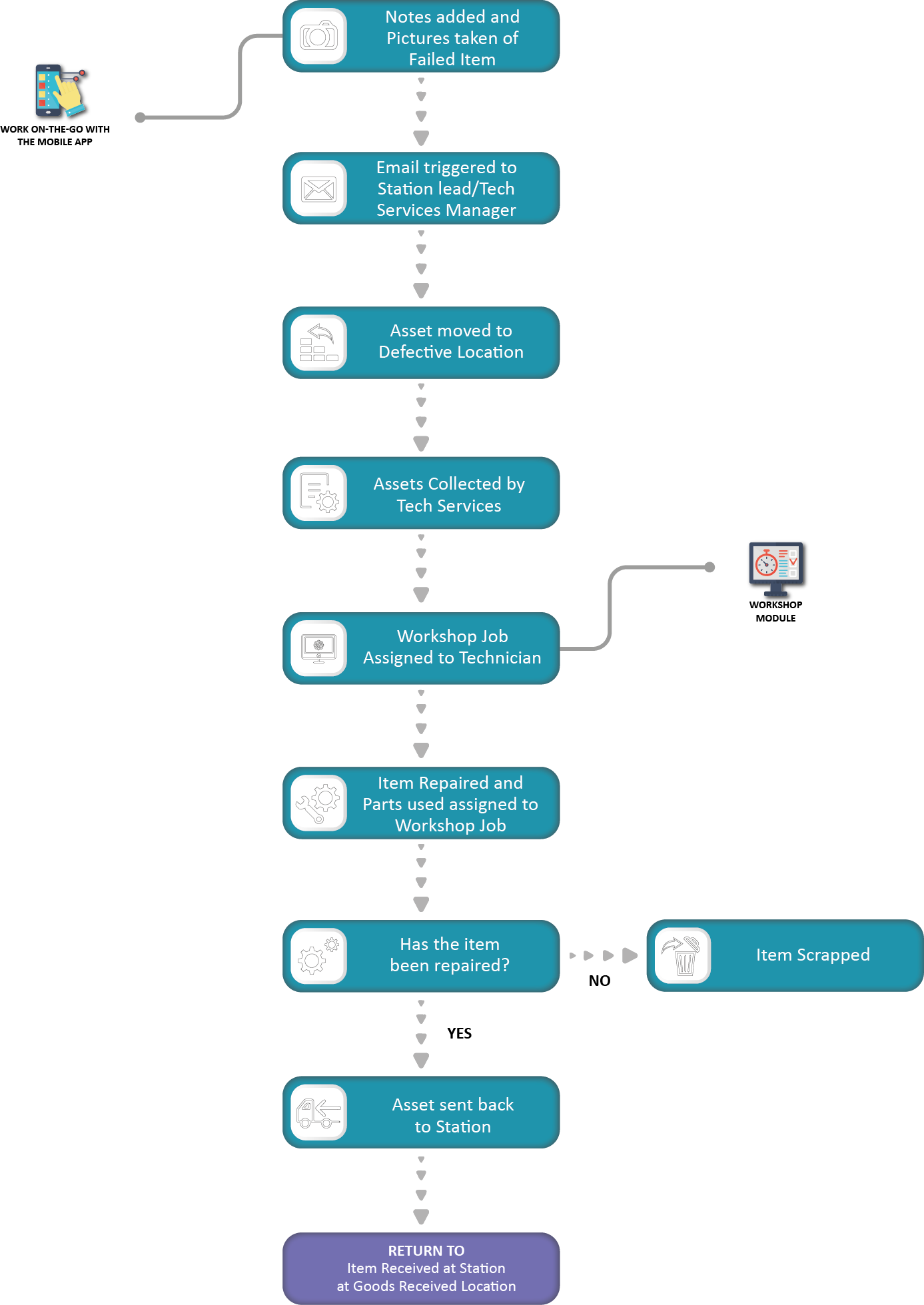

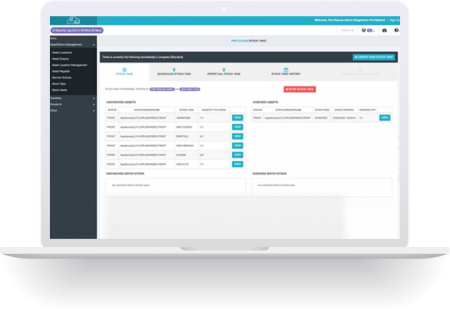

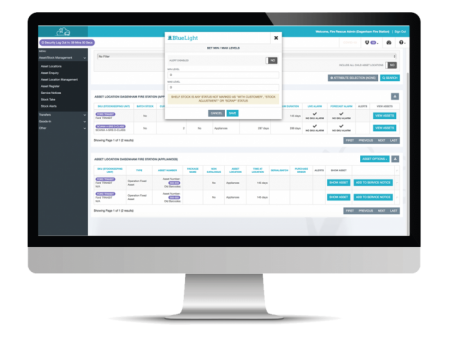

Pro-Cloud has been built around assets, offering the highest levels of stock visibility back at base and out in the field. Every stock movement is managed, including real time usage and valuation.

The integrated nature of the Pro-Cloud goods in procedure, activity completion, scrap, and stock loss functions are all integrated into hand-held scanning devices, ensuring that every asset movement is recorded in real time. This is where stock takes occur and alerts are generated when stock reaches a certain threshold, providing a centralised stock management solution that will monitor stock levels and track financials, building in equipment depreciation.

Offering only the best asset tagging options

Each asset has a unique tracking ID number, which is created from GRN (goods received notice) to scrap, enabling each asset movement to be recorded via mobile scanning technology. GS1 & EAN 128 barcodes, QR codes, NFC tags and RFID asset tags can all be used to ensure precise stock management of inventories.

Batch stock management

Pro-Cloud accommodates for a variety of stock including smaller items that we call batch items such as disposable consumables that are generally used by public safety organisations such as ambulance services. The system allows you to record the quantity of these batch items against a specific location label and monitor exactly how much comes in and out of that particular area. Whether it’s one tray on a warehouse rack or several containers across multiple locations, you can keep track of every single item going through your organisation with Pro-Cloud.

Core benefits include:

The ability to view stock levels in real-time

The use of legacy barcodes so there is no need to re-label items or locations

Perpetual and full stock takes

The ability to configure the system with minimum/maximum stock levels for automated stock replenishment

The use of batch stock numbers to differentiate between items.

The configuration of move rules to stop invalid asset moves, i.e. high value stock cannot be scrapped without authorisation